Esperanto

Esperanto

Shqiptare

Shqiptare

Euskara

Euskara

Zulu

Zulu

Latinus

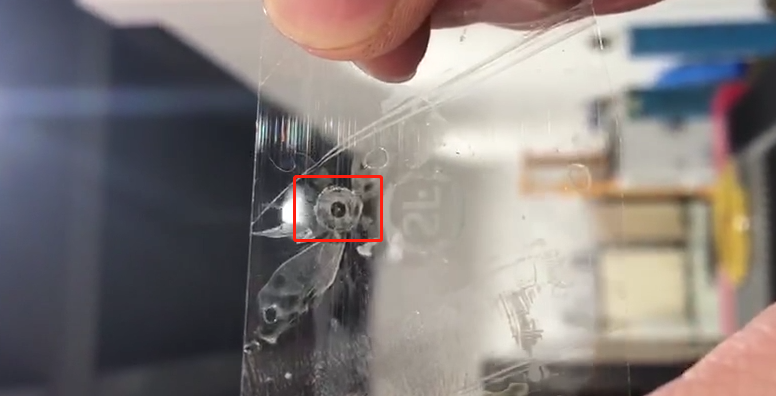

Latinus

Cymraeg

Cymraeg

தமிழ்

தமிழ்

Slovak

Slovak

Slovak

Slovak

Afrikaans

Afrikaans

ALS maintenance classroom (5) Replace ceramic ring

Posted on:

2023-08-12

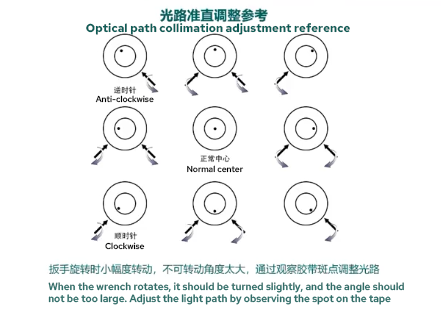

Precautions: After replacing the ceramic ring, it needs to be coaxially calibrated. The coaxiality directly affects the cutting quality. Poor coaxiality will cause one side to be cut well and the other side to be cut badly when cutting the iron plate. That is to say, the laser beam and gas, the laser beam need to be shot from the middle of the nozzle.

Preparation tools: transparent tape, new ceramic ring

Operation steps:

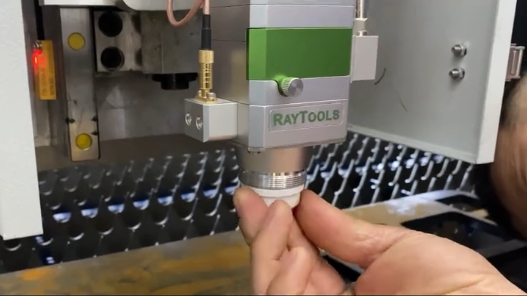

1. Loosen the lock nut of the ceramic ring clockwise

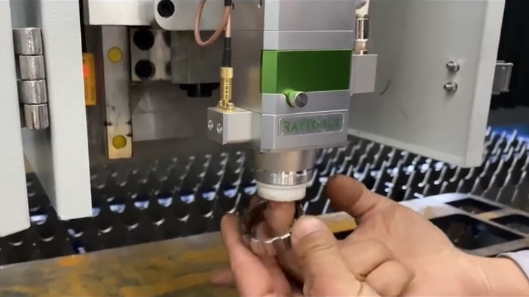

2. Prepare a new ceramic ring and align the small copper point on the ceramic ring with the cutting head

3. Put the lock nut of the ceramic ring on the finger and hold the finger against the ceramic ring

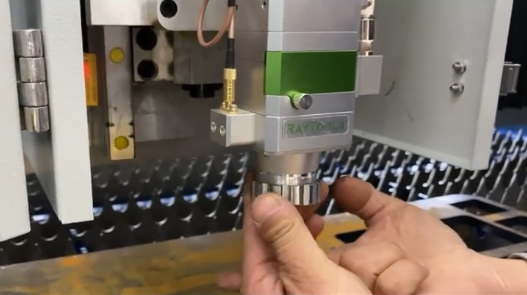

4. Tighten the ceramic ring locknut counterclockwise

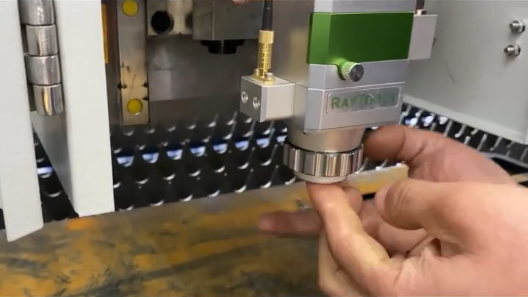

5. Finally tighten the nozzle counterclockwise

6. After replacing a new ceramic ring, it needs to be calibrated before it can work

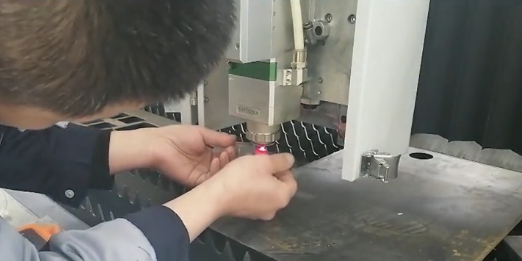

7. Take a piece of transparent tape and stick it under the nozzle

8."Open the shutter" on the remote control panel, and then press "Laser Spot"

9. Check whether the light output point is in the center of the nozzle. The light output point is in the center of the nozzle, which means that the coaxial connection is successful and the cutting can be carried out (if the light output point is not in the center, the position of the lower focus lens needs to be adjusted)

Related Info