Esperanto

Esperanto

Shqiptare

Shqiptare

Euskara

Euskara

Zulu

Zulu

Latinus

Latinus

Cymraeg

Cymraeg

தமிழ்

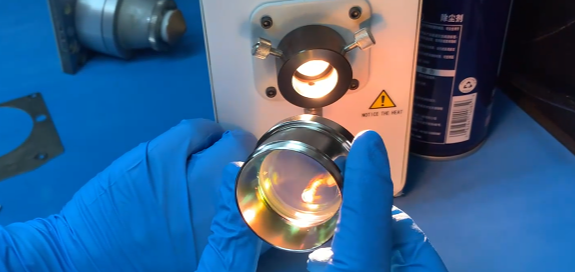

தமிழ்

Slovak

Slovak

Slovak

Slovak

Afrikaans

Afrikaans

ALS Maintenance Classroom (2) | Replacing Collimators

Posted on:

2023-07-21

Precautions:

(1) Please operate in a dust-free room

(2) It is better not to install lenses with naked fingers, but wear disposable anti-static gloves

(3) Do not use suction instruments to avoid scratching the lens surface

(4) Avoid talking above the lens and keep away from things that are easy to pollute

(5) Do not touch the film when taking the lens, and hold the edge of the lens

(6) Be careful not to let hard objects touch the polished surface of the lens

(7) After replacing the collimator, it is necessary to calibrate it by coaxing

Prepare tools:

① Isopropanol ② dust-free cotton swab ③ dust-free cloth ④ Allen wrench ⑤ dust remover ⑥ Disposable anti-static gloves

⑦ Optical fiber cold light source machine

⑧ New collimator ⑨ Transparent tape

Operation steps:

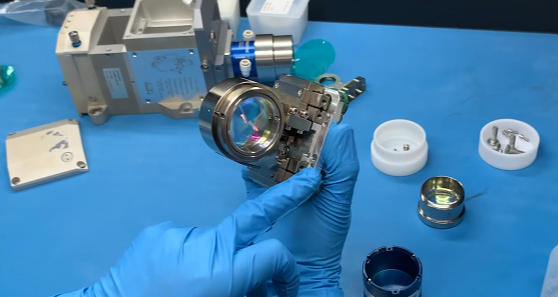

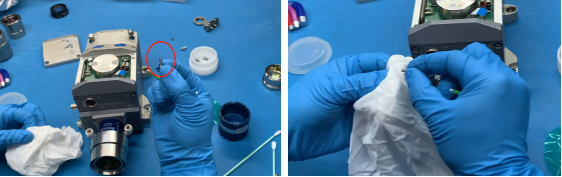

1. Remove the cover plate of the collimator first, loosen the screws one by one in a diagonal way, and keep the stress on each corner uniform without damaging the bolts

2. Screws are coated, please place them separately

3. Loosen the internal components with a small wrench

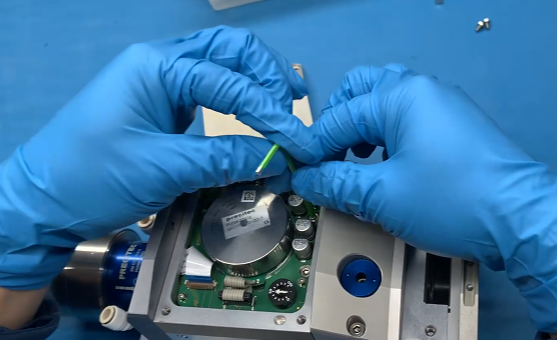

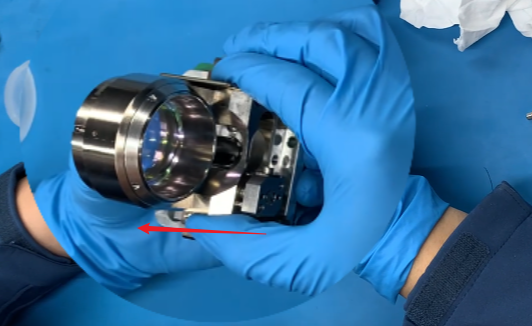

4. Slightly pull out the cable here

5. Loosen the screws under the flat wire, and the other screws are still loosened in a diagonal way

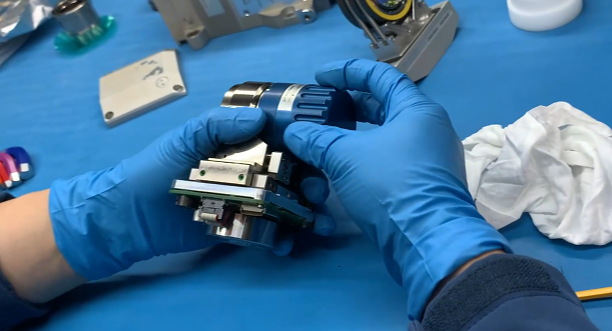

6. Rotate the motor left and right, and the motor must be rotated to the middle position to open

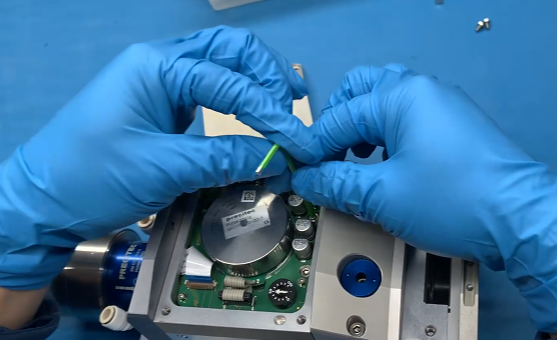

7. Vertical on the desktop

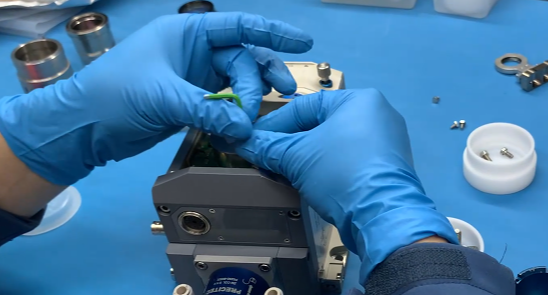

8. Clean the mirror removal tool before replacing the collimator group

9. Push the base to the left and align the right side

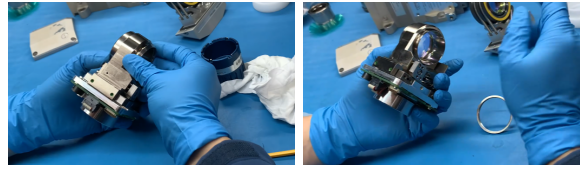

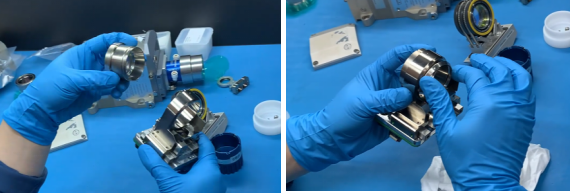

10. Use the mirror removal tool to turn and unscrew

11. Take down the metal ring

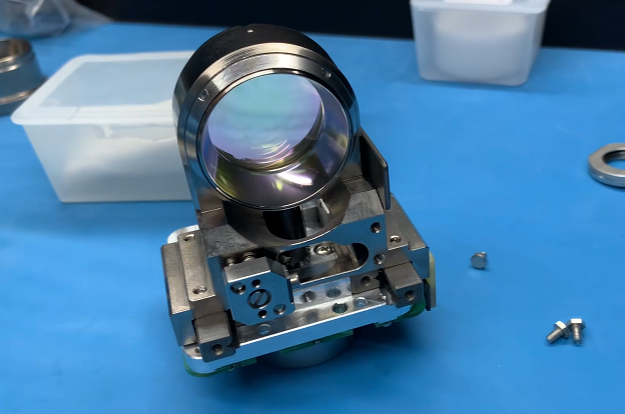

12. Remove the damaged collimator

13. Look at the cold light source to see if there are black spots on the lens

14. There is black burning point, and a new collimator needs to be replaced

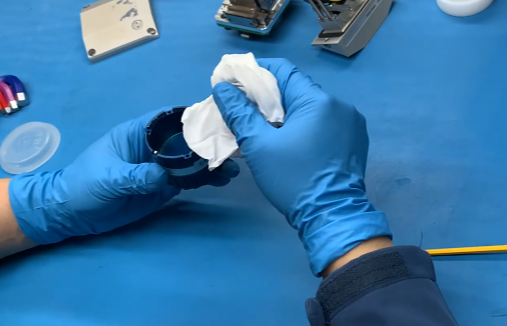

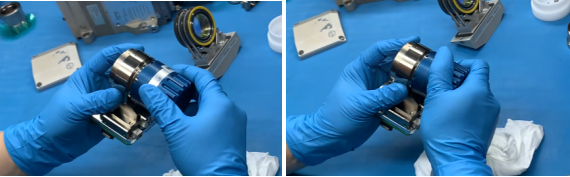

15. Clean the dust on the base and card slot with a cotton swab

16. Use professional dust remover for secondary cleaning

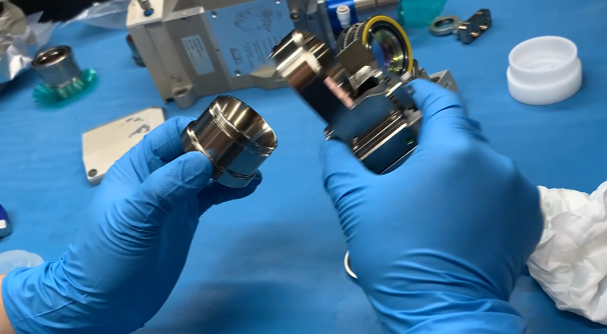

17. Replace the collimator with a new one and install the metal ring

18. Use the mirror removal tool to tighten

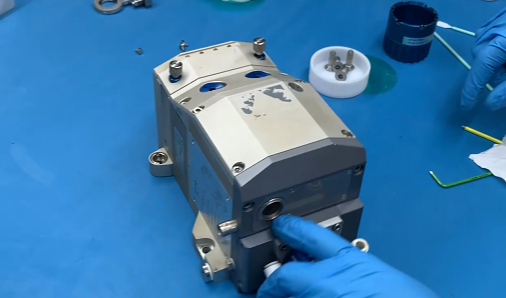

19. Pay attention to the position when placing, align and place the positioning pin here

20. Clean the dust on the wrench and screw

21. Tighten each screw diagonally

22. Pull down the flat cable and fasten it

23. Fasten the cover plate and tighten the screws one by one

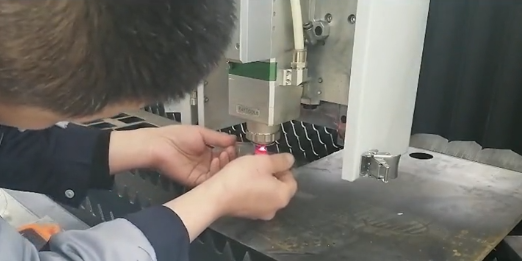

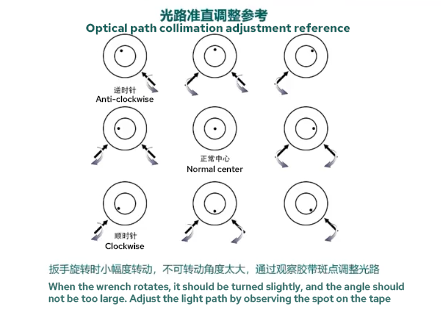

24. After replacement, it is necessary to find the laser center point by coaxing (this is because the production process of each factory is different, and the error range is also different). The specific operation method is as follows:

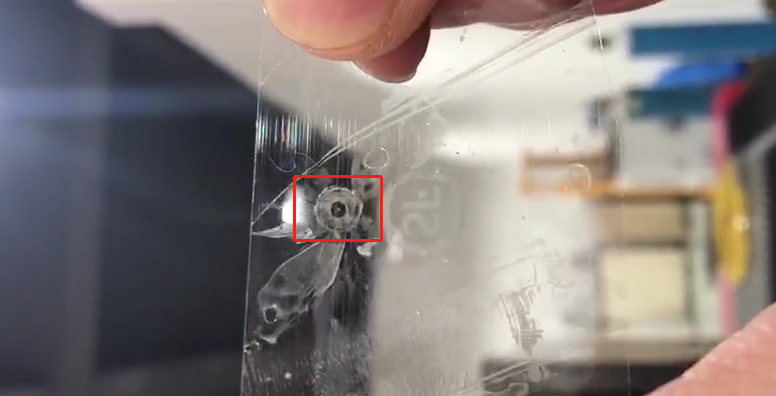

25. Take a piece of transparent tape and stick it under the nozzle

26. "Open the shutter" on the remote control panel, and then press "Laser Spot"

27. Check whether the light output point is in the center of the nozzle. The light output point is in the center of the nozzle, indicating that the coaxiality is successful and the cutting can be carried out (if the light output point is not in the center, the position of the lower focus lens needs to be adjusted)

Related Info