Esperanto

Esperanto

Shqiptare

Shqiptare

Euskara

Euskara

Zulu

Zulu

Latinus

Latinus

Cymraeg

Cymraeg

தமிழ்

தமிழ்

Slovak

Slovak

Slovak

Slovak

Afrikaans

Afrikaans

Focusing lenses

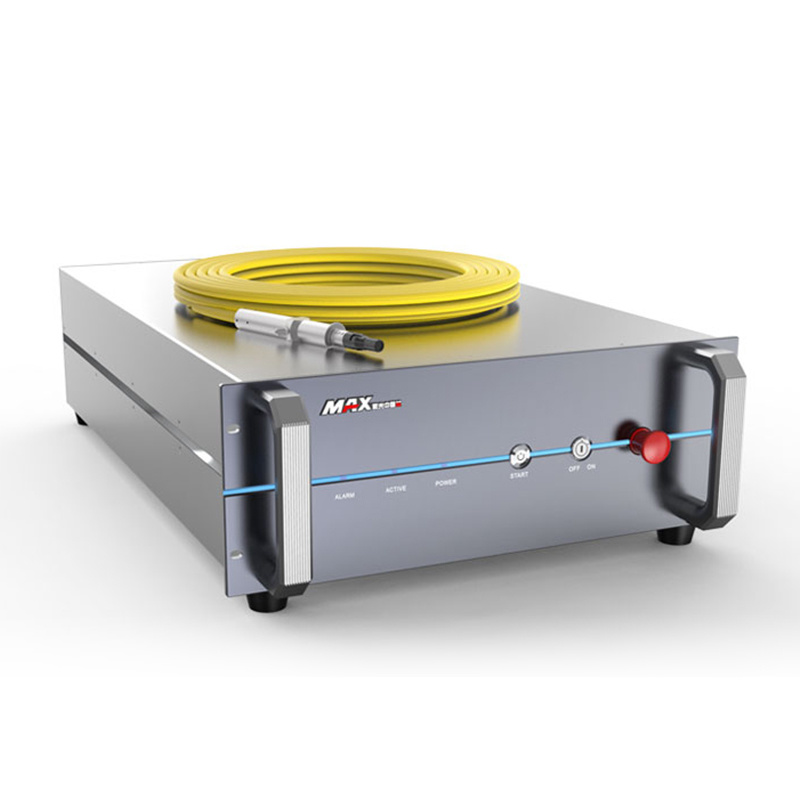

At present, laser welding is mainly divided into welding with a fixed-light path system and scanning field mirror welding. The fixed optical system uses a collimating mirror to collimate the light emitted from the optical fiber and then uses a focusing mirror to focus on the joint to be welded, while the scanning field mirror welding is a process that uses a scanning field mirror instead of a focusing mirror to focus the welding. Translated with www.DeepL.com/Translator (free version)

Category:

Focusing Lenses

Keywords:

Details

|

Part Category

|

Diameter (mm) | Focal Length (mm) |

Coating

|

|

|---|---|---|---|---|

|

Fiber Cutting Focusing Lens

|

Spherical/Aspherical

|

25

|

100

|

AR/AR@1030-1090mm

|

| 25 | 125 | |||

| 28 | 100 | |||

| 28 | 125 | |||

| 30 | 125 | |||

| 30 | 150 | |||

| 30 | 200 | |||

| 37 | 125 | |||

| 37 | 150 | |||

| 37 | 200 | |||

|

38.1

|

125 | |||

|

38.1

|

150 | |||

|

38.1

|

175 | |||

|

38.1

|

200 | |||

| 50 | 150 | |||

| 50 | 200 | |||

| 50 | 250 | |||

| 52 | 200 | |||

| 52 | 250 | |||

Focusing lenses are essential optical components used in a wide range of applications to control and manipulate light. These lenses play a crucial role in directing light rays to achieve precise focusing, magnification, or collimation, depending on the specific requirements of the system.

One of the key features of focusing lenses is their ability to converge or diverge light rays. By altering the curvature of the lens surfaces, focusing lenses can bend incoming light rays to a specific focal point, where they either converge to form a sharp image or diverge to create a parallel beam. This property makes focusing lenses indispensable in various optical systems, such as cameras, microscopes, telescopes, and laser systems.

Focusing lenses come in different shapes and configurations to suit different applications. Convex lenses, for example, are commonly used to converge light rays and form real or virtual images, while concave lenses are employed to diverge light rays and correct optical aberrations. Additionally, specialized lenses like cylindrical lenses and doublet lenses are used for specific purposes such as astigmatism correction and color correction in optical systems.

Another important characteristic of focusing lenses is their ability to control the focal length and numerical aperture of the optical system. The focal length of a lens determines its magnification power and working distance, while the numerical aperture dictates the light-gathering ability and resolution of the system. By selecting the appropriate focusing lens with the desired focal length and numerical aperture, optical designers can optimize the performance of the system for specific imaging or illumination tasks.

Focusing lenses are also designed to minimize optical aberrations and distortions that can degrade image quality. Manufacturers utilize advanced materials and precision manufacturing techniques to produce high-quality lenses with minimal spherical aberration, chromatic aberration, and distortion. This ensures that the focused light remains sharp, clear, and free from unwanted artifacts, resulting in superior imaging performance.

Furthermore, focusing lenses are often coated with anti-reflective coatings to enhance light transmission and reduce surface reflections. These coatings help improve the overall efficiency of the optical system by minimizing light loss and ghosting effects, particularly in high-powered laser systems and imaging setups.

In conclusion, focusing lenses are versatile optical components that play a critical role in controlling and manipulating light in various applications. With their ability to converge or diverge light rays, shape the beam profile, control focal length and numerical aperture, and minimize optical aberrations, focusing lenses are indispensable tools for achieving precise imaging, magnification, and illumination in optical systems. Their design flexibility, optical performance, and reliability make them essential components in a wide range of industries, including microscopy, photography, astronomy, and laser technology.

Services

We always put our commitment to customers in the first place and enforce industry product quality standards.

Under normal circumstances, all products covered in this booklet have a shelf life of one year from the day they are delivered to the customer, and the warranty time is calculated as if the product were not opened in its packaging. After opening the package and using it, it is not covered by the warranty period, except for the laser cutting head.

We ensure the parameters of the products, if the product quality is not qualified, we will give free replacement.

Prev

Related Product

Consult us

If you are interested in our products, please leave your email and we will contact you as soon as possible, thank you!